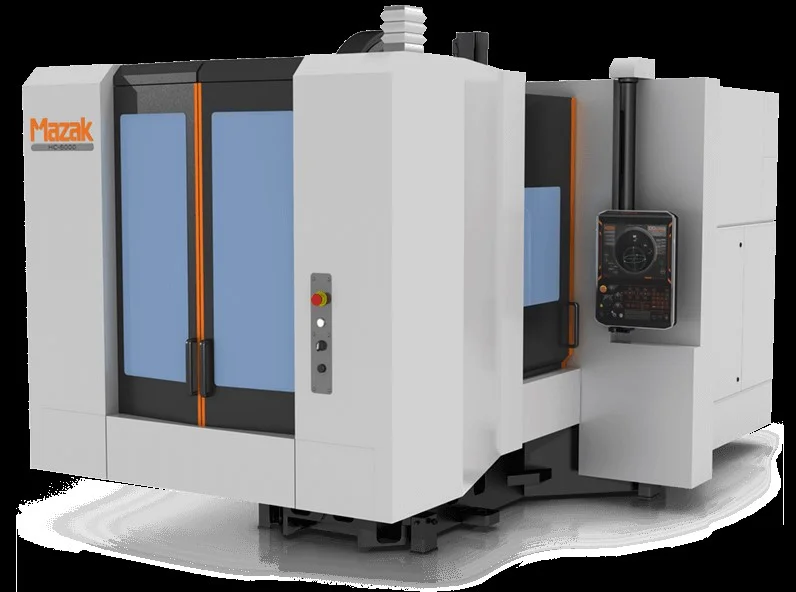

A Horizontal Machining Center has a spindle that is oriented horizontally. This allows the spindle to cut materials without leaving metal chips. The chips will fall off the material and will not get into the tool. This type of center has a lower tool life than a vertical one, but it has a better surface finish.

4th axis

4th-axis horizontal machining centers allow the machining of more complex shapes. They can also handle multiple tools at once. Often used for tombstone machining, this type of machine can perform multiple machining tasks at the same time. These machines are commonly integrated with automation equipment, such as robotic arms or pallet changers.

Elaborate Fixturing

An HMC can do the work of three VMCs, which means fewer operators are needed. They also offer a higher ROI. HMCs can require more elaborate fixturing, which may cost more. However, HMCs require less training for operators.

Rigid Worktable

The rigid worktable of a horizontal machining center is a great feature, since it allows for angular cuts. Whether the workpiece is a pipe or a bar, this machine can handle it. Additionally, it has a pallet changer that can accommodate multiple tool sizes.

Edged or Sharp Edges

In addition, these machines are capable of machining parts with edged or sharp edges. They also can handle multi-sided parts. This feature helps reduce the need for multiple set-ups, which can increase productivity.

Spindle in Horizontal Orientation

Horizontal machining centers are high-end machine tools that are able to handle workpieces with four faces. These machines feature rigid worktables that allow easy access to the workpiece and provide a large work envelope. This configuration is also a better choice for machining large objects. Unlike vertical machining centers, horizontal machines have a spindle that moves vertically instead of horizontally.

Flat Surfaces and Mill Slots

Vertical machining centers are similar to horizontal machines, but they have a vertical spindle axis. The machine is used to cut flat surfaces and mill slots. These machines are also capable of machining complex geometries, making them ideal for large parts and very intricate designs. In addition to their versatility, these machines are very cost-effective and can be found in a wide variety of industries.

Pallet Changers

Horizontal machining centers typically come with pallet changers that allow parts to be preloaded onto the fixtures. This feature improves productivity by reducing load and unload time. The automated pallet changers also enable machines to be operated with minimal human intervention. In addition to these advantages, horizontal machines are more reliable. They typically feature longer tool lives and higher machining efficiency. This translates to better productivity and profitability.

Cost

The cost of Horizontal Machining Centers (HMCs) can range greatly. This is due in part to the construction and design of the machine. The cost of work holding may also vary. An HMC may cost more than a VMC but is often justified by its increased productivity.

Vertical Machining Centers

HMCs can replace many vertical machining centers and can free up floor space. Some models come with large tool magazines and are equipped with specialized tools such as deburring. A horizontal machine can perform deburring very efficiently. The structure of the machine makes it easy to remove the material.

Accomplishing all Machining in Two Setups

An HMC can save a shop a great deal of time. Because it is capable of accomplishing all machining in two setups, it will take less time than a single vertical. With a single HMC, a part can be machined in the same cycle as all three datums. In this way, a single horizontal can do the work of three or four verticals, reducing the total machining time by as much as 6 hours. This is not including the setup time.

Advantages

Horizontal machining centers have a number of benefits. One of them is that they require only a single setup, which minimizes the risk of human error and rework. Another benefit is that they are capable of taking on larger workpieces and can reduce cycle time.

Benefits

In addition to these benefits, horizontal machining centers can help reduce costs. These centers can cut down on coolant and labor costs. They can also provide automation to your machining process, allowing you to focus your production team on higher-priority items. And with their horizontal design, horizontal machining centers can also improve productivity.

Able to Cut Cycle Time

One shop found that an HMC was able to cut cycle time by half and cut costs by 25%. They also had fewer operators than a VMC. In addition to lower production costs, HMCs also can handle more complex machining operations than VMC. Ultimately, they can propel your shop into a new category of manufacturing.